Automation rules for WMS make warehouse work simple and fast. A rule tells the WMS what to do when events happen. Rules can move products and update stock by assigning tasks. They cut errors and save time for staff.

But how do you create automation rules for a WMS? This is what this article will focus on. It will provide you with a comprehensive idea of how to create automation rules for better warehouse management.

What are Automation Rules?

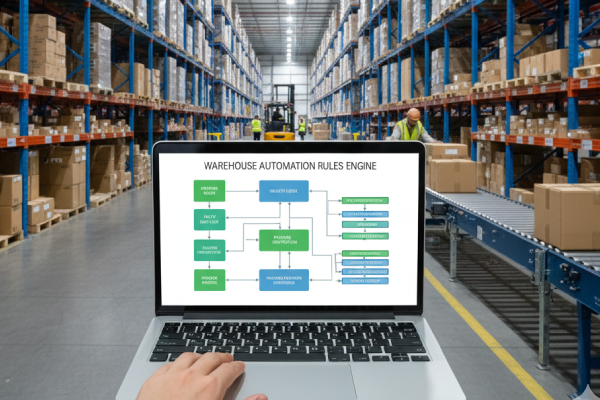

Automation rules tell a WMS how to act when certain events occur. They match conditions to actions. Rules can route picks or move stock. They can even alert staff when a count drops. For example, a rule can move received items to a fast pick zone.

Another rule can hold damaged goods and flag them for review. So, what are automation rules in simple terms? It is a set of rules that simplifies work. They cut repetitive tasks and make work faster.

What is Rule-Based Automation for Warehouse Management?

So, what is rule-based automation? It means the WMS follows set rules that humans create. Each rule has a clear trigger and a clear action. Triggers include scans, time windows, or inventory levels.

Actions can include putaway, pick assignment, or label printing. This model is easy to test because you can see cause and effect. It fits teams that want clear steps and quick wins. Good rule design lowers mistakes and saves staff time.

Step-by-Step Process to Create Automation Rules for Warehouse Management

It is important to have the right set of automation rules for warehouse workflow management. Doing so will ensure that the work gets done without any disruptions. Here is a step-by-step process that can help you create automation rules for WMS.

-

Step 1 – Assess Your Warehouse Needs

Walk the floor and write down tasks that repeat. You should keep a Note of where picks stop or errors rise. Talk to packers and pickers. It is best to prioritize tasks by how much time they waste or how often they fail. A good rule solves a clear problem. Keep goals small at first so you can test rules fast.

-

Step 2 – Select Your Technology

Pick a WMS that lets you set rules without code. Check for a visual rule editor and good logs. Ask vendors if their system knows what WMS automation is. You can show examples. Ensure the system works with scanners, printers, and your ERP. Confirm backups and version control for rules.

-

Step 3 – Create and Implement Rules

Write rules using simple language. Name each rule clearly. Example: “Auto-putaway for carton type A”. Test rules in a sandbox or staging area. Use sample SKUs and mock orders to see results. You can also include rollback steps if a rule fails.

In addition to that, ask operators for feedback and update rules as needed. Document each rule’s purpose and owner. Ask for clarity when naming and documenting each rule.

-

Step 4 – Review and Save

Run reports to see how rules affect throughput and errors. Keep a change log and note who made edits. Adjust thresholds that trigger actions to reduce false alarms. Save versions so you can restore older settings. Schedule regular reviews and train staff on changes.

Additional Tips to Help You Out with Automation Rules for WMS

There are some other things that can also play a key role in creating automation rules for WMS. It will ensure that you can get the job done with your WMS. Here are a few tips to help you out:

- Link rules to your ERP and carriers so data flows smoothly. Test data paths and error handling. Good integration stops manual fixes.

- Build rule templates for common tasks like putaway and replenishment, as templates save time and keep names consistent.

- Avoid too many rules firing at once. Watch for rule loops where one rule keeps triggering another. Use limits and delays to stop loops.

- Keep detailed audit logs for rule edits and record who changed what and why, as these logs meet audit checks and help trace problems fast during reviews.

- Use templates and mapping to scale rules across sites. Pilot rules at one site, monitor results, then roll out in phases with clear checks.

- Repeat audits quarterly and report findings.

Wrapping Up

Automation rules for WMS bring order to chaos. It is best to start small and track results to test. Clear rules cut errors, save time, and boost team confidence. Keep logs and train staff so the rules stay helpful.

Review rules regularly and improve them based on real data, and repeat improvements on a schedule. Work with WizeFulfill to automate WMS rules, cut errors, and speed fulfillment using clear rules and trusted support right away.